NEWS

A Mass Timber Tower Rises in Portland

By Will Macht | November 19, 2018

Upon completion at eight stories, Carbon 12 was the tallest CLT mass timber building in the United States. (Andrew Pogue)

Originally published in Urbanland.

Until recently, buildings taller than five stories had to be constructed of steel or reinforced concrete, both of which require about 80 percent more energy to produce and represent about 200 percent more greenhouse gas emissions than cross-laminated timber (CLT), a new engineered wood product.

Portland developer Ben Kaiser of the Kaiser Group recently completed the tallest American CLT mass timber building—an eight-story, 16-unit condominium/retail tower on an 8,470-square-foot (787 sq m) lot. (Another tower rising in Portland will soon surpass that height.) Residents enter the building—designed with only two units per floor—directly from an elevator into their own units. Light and ventilation from three directions around the condo units give them more the feeling of a house than of an apartment. The combination of exposed CLT wooden ceilings and exposed glulam posts and beams on a 12-by-12-foot (3.7 sq m) and 12-by-15-foot (3.7 by 4.6 m) grid, along with oak floors, lends a warm wooden patina to the units offset by vertical white drywall panels between the windows around the unit and in the kitchens and the bathrooms.

With two retail units on the ground floor for lease to a café and a credit union, and an 85-foot (26 m) zoning height limit, only 14 residential units could be included in the tower. Therefore, they needed to be large enough to attract an exclusive market, yet small enough to be affordable to that new market for Portland’s east side. Kaiser settled on 1,551-square-foot (144 sq m) two-bedroom, two-bathroom units in which one of the bedrooms could enlarge the central great room. Each unit has a 16.5-by-11.3-foot (5 by 3.5 m) deck facing north or south.

The building is called Carbon 12 for the most common carbon isotope the engineered wood sequesters, and for the building’s address at 12 NE Fremont Street in Portland. Typically, CLT panels are made of five layers of wood glued at right angles to one another under high pressure to form solid panels usually measuring about 12 feet wide and up to 60 feet long (3.7 by 18 m) and two to 24 inches (5 to 60 cm) thick. CLT enables developers to create tall, strong, energy-efficient, and earthquake- and fire-resistant buildings. CLT is made from sustainably managed forests from logs under nine inches (23 cm) in diameter. An acre (0.4 ha) of forest can absorb and sequester twice the carbon dioxide produced by the average car driven for a year.

The Structure

Carbon 12 is designed, metaphorically, like a tree—a design that reduces the structural need for a concrete foundation and is akin to a sophisticated pole building. (Kaiser Group)

Carbon 12 is designed, metaphorically, like a tree—a design that reduces the structural need for a concrete foundation and is akin to a sophisticated pole building. (Kaiser Group)

Carbon 12 is designed, metaphorically, like a tree. Its roots are a forest of steel piles driven 45 feet (14 m) deep into the ground to secure resistance to seismic pressures below and to wind loads above. The piles support a three-dimensional grid of glulam posts and beams onto which CLT panels measuring 37 by 11 feet (3 by 11 m) are lifted and locked into place. Plywood splines bind these panels to form an exceptionally solid diaphragm. Structurlam Mass Timber Corporation, based in Penticton, British Columbia, Canada, prefabricated the large CLT panels and glulam posts and beams. Tolerances were so tight that an entire floor was lifted by a crane and locked into place in less than five days.

Structural loads are borne by a grid of glulam posts tied to the deep piles onto which CLT panels are lifted and locked into place over steel tubes welded onto heavy steel plates attached to the ends of the columns. (Kaiser Group)

Ceilings are 9.5 feet (2.9 m) high and the Douglas fir lower layer of the CLT panels is exposed. To prevent the transmission of sound between units, the same CLT panels cannot be exposed as floors of the units above. Instead, they are coated with 1.5 inches (3.8 cm) of gypcrete, a lightweight concrete floated into place on top of which are 1.5 inches (3.8 cm) of sound insulation board and a one-eighth-inch (3.1 mm) rubber mat under engineered oak flooring.

Structural loads are borne by a grid of glulam posts tied to the deep piles onto which CLT panels are lifted and locked into place over steel tubes welded onto heavy steel plates attached to the ends of the columns. (Kaiser Group)

Advantages of CLT

Kaiser found the following reasons to experiment with a tower built with CLT panels:

They match steel and concrete in structural performance, but are only 20 percent of their weight and allow for the use of smaller cranes.

The panels thermally outperform concrete and steel.

They are seismically resilient.

Panels are prefabricated off site during foundation construction and are shipped for just-in-time scheduling, reducing the need for on-site storage.

Using CLT can shorten construction schedules by up to 40 percent, reducing construction loan interest and land carrying costs, allowing units to be sold or rented earlier, which increases absorption and cash flow.

Zoning Negotiations

Top, left: Carbon 12 is the northern part of a 1.1-acre (0.5 ha) site southeast of Kaiser’s three-building office and retail project that became One North/Radiator at the intersection of North Williams Street and NE Fremont Street, and just west of a grocery store. (Kaiser Group)

Carbon 12 is the first phase of a larger project. Starting in 2004, Kaiser bought seven lots to aggregate 1.1 acres (0.5 ha) of land just southeast of his earlier Radiator office and retail project and just west of a new grocery store. Those projects in inner northeast Portland helped the area change from its former character as a low- and moderate-income area comprising single-family houses into a trendy area of mixed-use buildings.

Click to zoom. Top, left: Carbon 12 is the northern part of a 1.1-acre (0.5 ha) site southeast of Kaiser’s three-building office and retail project that became One North/Radiator at the intersection of North Williams Street and NE Fremont Street, and just west of a grocery store. (Kaiser Group)

Kaiser’s land was zoned R2, which is a multifamily zone allowing one unit per 2,000 square feet (186 sq m), which would have allowed 22 to 32 units per acre (55 to 80 per ha). For a mixed-use structure, Kaiser sought a zone change to EX, a central employment zone allowing for a full range of high-density commercial, light industrial, institutional, and residential uses at least 65 feet (20 m) high. The Eliot Neighborhood Association (ENA) protested the project’s compatibility with the existing predominantly single-family neighborhood but did agree to a change to RX, a high-density residential zone that actually allowed residential buildings up to 100 feet (30 m) high and over 100 units per acre (247 per ha), limits the ENA later protested.

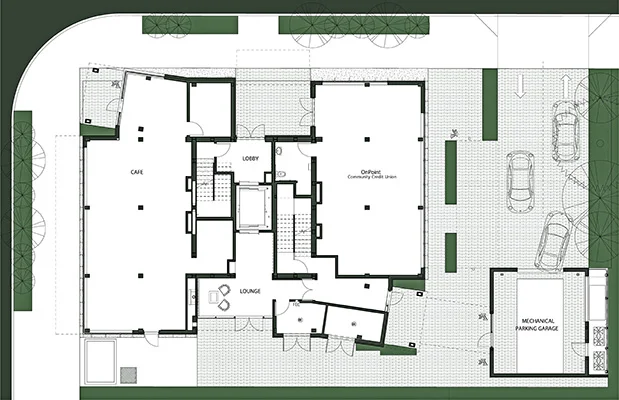

The ground floor houses a café on the west and a credit union on the east. Residents park in a robotic parking garage entered at the southeast corner of the site. (Kaiser Group)

At the city council meeting ruling on the zone change, Kaiser offered to step the height limits down to 85 feet (26 m) on the northwest corner, to 65 feet (20 m) in the center, and to 45 feet (14 m) at the eastern property lines. “In the course of five minutes, we threw out a $100,000 zone change—all the studies, all the architectural drawings, all the work done by the city, the planners—and settled on what it is now,” Kaiser says. “This is what allowed us to explore tall timber because that corner was preserved at 85 feet.”

The ground floor houses a café on the west and a credit union on the east. Residents park in a robotic parking garage entered at the southeast corner of the site. (Kaiser Group)

Site Design

A six-story, 110,000-square-foot (10,000 sq m), mixed-use project with a 70-unit elder housing building stands next to a 17-unit retail component called Makers’ Alley with small, affordable spaces for Portland’s burgeoning artisanal and small-craft industries. (Kaiser Group)

A six-story, 110,000-square-foot (10,000 sq m), mixed-use project with a 70-unit elder housing building stands next to a 17-unit retail component called Makers’ Alley with small, affordable spaces for Portland’s burgeoning artisanal and small-craft industries. (Kaiser Group)

The design for the larger site was a function of both the outsized 240-by-600-foot block (73 by 183 m)—deviating from Portland’s 200-by-200-foot blocks—and the varied zoning permitted within it. The 85-foot (26 m) height limit applied only to the small 70-by-121-foot (21 by 37 m) northwest corner tax lot that houses the tower, so Kaiser designed the tallest building he could using the CLT tower like a campanile (a freestanding bell tower in Italian towns) announcing the center of a transforming urban mixed-use neighborhood in close-in Portland.

For the remainder of the site, Kaiser designed a six-story, 110,000-square-foot (10,000 sq m) mixed-use project called Canyons with a 70-unit elder housing building, also built using CLT panels, next to a 17-unit retail component that he calls Makers’ Alley with small, affordable spaces for Portland’s burgeoning artisanal and small-craft industries. Eleven of those units are to be only one story, neighboring the single-family houses there. Including retail units, the CLT buildings on the whole site achieve a density of 94 units per acre (235 units per ha).

Robotic Parking

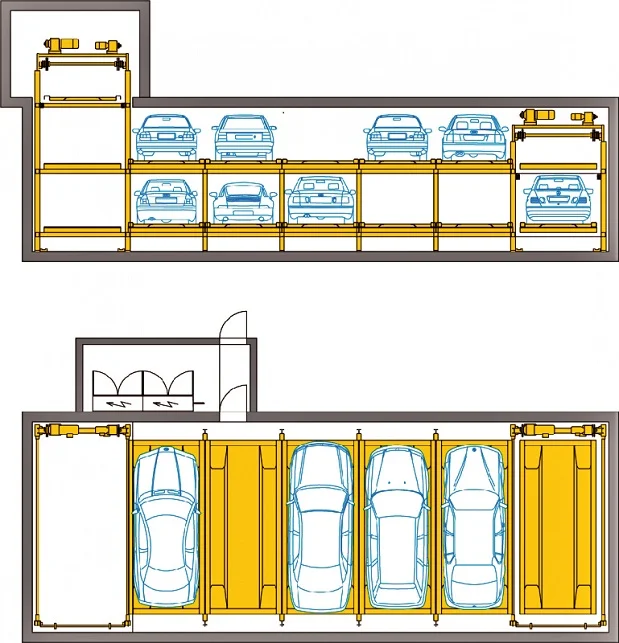

The Wohr Levelparker 590 model robotic system was designed for small-footprint areas. Carbon 12’s installation houses 22 cars in a space that comes to less than 90 square feet (8 sq m) per space, which amounts to only about 20 percent of a traditional parking structure. (Wohr GMBH)

To sell high-end condominiums at premium prices to buyers who almost certainly would own cars, Kaiser needed to provide enough parking. On a site as small as the tower’s, building underground parking would have required underground ramps steeper than the code allowed or which spiraled so much as to have yielded too few spaces. Besides, the CLT tower’s small-grid, deep piling would have interfered with parking. So, Kaiser experimented with an automated underground parking system made by Wohr GmbH, a company based in Friolzheim, Germany. While mechanical parking lifts have been installed in Portland, this is the first fully robotic parking system in Oregon.

The Wohr Levelparker 590 model robotic system was designed for small-footprint areas. Carbon 12’s installation houses 22 cars in a space that comes to less than 90 square feet (8 sq m) per space, which amounts to only about 20 percent of a traditional parking structure. (Wohr GMBH)

The Wohr Levelparker 590 model robotic system was designed for small-footprint areas. Carbon 12’s installation houses 22 cars in a 1,953-square-foot, 93-by-21-foot (181 sq m, 28 by 6 m) space. That is less than 90 square feet (8 sq m) per space—only about 20 percent of the space provided in a traditional parking structure. Residents drive into a 456-square-foot (42 sq m) single-car garage onto a pallet. After getting out of the car, residents enter a code into a keypad to lower the pallet onto a turn-table—which rotates the car for easy exiting—on the upper of two underground levels. The system then moves like a horizontal Ferris wheel to place the pallet into a storage location. When residents order retrieval, the system cycles the conveyor to deliver the car pallet to the entry lift where it rises to the garage, pointing outward, and the resident can drive off. Unlike conventional parking structures, no special ventilation, lighting, or security is required; no elevators, stairs, or fire exits are needed to move patrons; cars are safe from damage, theft, and vandalism; and no vehicle emissions can seep into the building above.

The robotic parking system stores 22 cars on two underground levels. Unlike parking structures, no special ventilation, lighting, or security is required; no elevators, stairs, or fire exits are needed to move patrons; cars are safe from damage, theft, and vandalism; and no vehicle emissions can seep into the building above. (Harding Steel)

The robotic system cost $1.1 million to install, which comes to $50,000 per space. In addition, 43,000 cubic feet (1,200 cu m) of soil was excavated between the pilings to build the concrete vault to house it. If costs were isolated for the excavation and concrete vault, Kaiser thinks that might have added another $20,000 per space. He allocated these expensive spaces at one per unit for the six units on the three lower floors, and two per unit to the eight units on the upper four floors.

The robotic parking system stores 22 cars on two underground levels. Unlike parking structures, no special ventilation, lighting, or security is required; no elevators, stairs, or fire exits are needed to move patrons; cars are safe from damage, theft, and vandalism; and no vehicle emissions can seep into the building above. (Harding Steel)

Market

Above: The combination of exposed CLT wooden ceilings and exposed glulam posts and beams on a grid with oak floors lends a warm wooden patina to the units, offset by vertical white drywall panels between the windows on the three sides of the unit and in the kitchens and bathrooms. Below: Each unit has a 16.5-by-11.3-foot (5 by 3.5 m) deck facing north or south. (Andrew Pogue)

Kaiser thought the market for this small number of higher-end condos would be downsizing baby boomers and other empty-nest couples who appreciate close-in urban living in a trendy area. Dual-income younger professional couples also might be prime targets. But in the first three months, seven of the 14 units were sold or pending to single, middle-aged professional women, who perhaps were attracted by direct-elevator access to units and the security of the parking system. All but one unit sold were on the three lowest floors, and were priced from $730,000 to $795,000. Prices on the top four floors ranged from $1.1 million to $1.35 million. This is unusual for the west side of Portland, where the highest-priced units at the tops of buildings are often among the first to sell.

Economics

Pioneering the tallest CLT building in the nation, and the first robotic parking system in Oregon, at premium prices on a single-family-house-sized lot, on a block where 1,000-square-foot (93 sq m) houses predominate, takes courage.

Kaiser says the total development cost was about $14.5 million, almost $600 per square foot ($6,500 per sq m) for salable/leasable area. But Kaiser has structured his business with multiple roles and profit centers as architect (through his firm Path Architecture), as developer and general contractor (through his firm Kaiser Group), and marketing and sales through Windermere, his wife’s firm. He obtained a construction loan of $10.3 million from Columbia Bank and provided about 30 percent equity. It also helped that he acquired and assembled the land for under $20 per square foot ($217 per sq m), a fraction of current values.

With sales averaging about $655 per square foot ($7,100 per sq m) and commercial leasing rates at $33 per square foot ($360 per sq m) triple-net, the high cost of developing innovative projects in Portland may trim profit margins. But with the learning curve for CLT buildings now completed, the developer’s low land cost basis, and a larger number of units to offset costs in the Canyons phase ahead, Kaiser may have advanced environmental stewardship for CLT mass timber buildings in an economically and environmentally sustainable way.

WILIAM P. MACHT is a professor of urban planning and development at the Center for Real Estate at Portland State University in Oregon and a development consultant. (Comments about projects profiled in this column, as well as proposals for future profiles, should be directed to the author.)

The evolution of office space has come to downtown Portland.

Nestled by the Willamette River in the Northwest Industrial District, the team of Project, Hacker and Lease Crutcher Lewis made a statement with Field Office.

Field Office is more than 300,000 square feet of office and retail space in two distinct, contemporary, six-story buildings surrounding a central courtyard that is meant to break down the barriers between indoors and outdoors.

There are times to celebrate small, boutique projects done well. This is not that. Field Office is a $61.5 million, LEED Platinum-certified statement about what office space can be in the 21st century.

Project wanted the development to reflect the Pacific Northwest, “a region people move to for lifestyle, and to be engaged by the outdoors and to be outside,” said Jonathan Ledesma, a partner at Project.

“For typical Class-A office, why do we find ourselves hermetically sealed in these boxes?” Ledesma said. Project wanted to “blur these lines between inside and outside.”

“WE WANT A TENANT THAT CAN APPRECIATE WHAT WE’VE DONE WITH FIELD OFFICE.”

— JONATHAN LEDESMA

To that end, each floor has its own outdoor patios with garden spaces planted with native flora chosen by Lango Hansen Landscape Architects. That’s meant to democratize outdoor spaces so every tenant has access to outside work and play spaces.

Mike Sager, project manager at Lease Crutcher Lewis, said the project team wanted to “break the paradigm of having people sit in cubicles with artificial lighting.”

Plenty of contemporary office developers talk about breaking out of cubicle culture, but Project went further than most with Field Office. On the ground floors of each building, the large windows roll up like garage doors. Bicycle-share users can park their bicycles outside. Interior hallways are lined with Forest Stewardship Council-certified woods, including juniper, cumaru and Douglas fir.

On a recent visit, tech employees were seated on wooden benches and stump-like chairs throughout the courtyard,

which includes a wetland space that is designed to accommodate winter rains. The plants will grow over time to appear more wild and natural. The flora was chosen around the idea of a restorative landscape reflecting what would grow there in a natural ecosystem.

The ground floor of the west building even includes a visually striking moss wall from Italian maker Benetti that acts like a furry and verdant green reminder of nearby Forest Park.

“We wanted to bring the outdoors in,” Ledesma said.

The entire roof area is committed to sustainability save for a photovoltaic array.

THE PROJECT TEAM OPTED FOR A SINGLE, UNUSUALLY TALL FLOOR OF PARKING. THAT ALLOWED THEM TO FIT 149 MECHANIZED LIFTS THAT PROVIDE 298 PARKING SPACES ON A SINGLE FLOOR.

The west building was completed first and has attracted large office tenants in Adpearance and Ampere. Other tenants include Four Point Legal; The Good, an e-commerce marketing firm; and Forth, an electric transportation nonprofit group. Commissary Café recently opened on the ground floor.

The slightly smaller east building is in want of an anchor tenant. A privately run gym, Formula Three Fitness, has opened there.

“We want a tenant that can appreciate what we’ve done with Field Office,” Ledesma said. “It’s a campus environment, not for one tenant, but for many tenants.”

Recruiting an east-building anchor tenant will presumably be the top priority for Field Office’s new owners. The project recently sold for $118 million to a joint venture of Goldman Sachs and Lincoln Property Co., brokerage firm Newmark Knight Frank announced recently.

Field Office came about from longtime partners. Both Lease Crutcher Lewis and Hacker had worked for Project previously, and were familiar with the developer’s large-scale vision and values.

Project acquired the site at 1895 and 2035 NW Front Ave. from Guardian Real Estate Services, paying $7.95 million in 2015, according to public records.

In building the development, the project team opted for a single, unusually tall floor of parking. That allowed them to fit 149 mechanized lifts that provide 298 parking spaces on a single floor. That saved the developer the expense of building a second floor of parking.

“We saved a substantial amount of money by not having to go down another floor,” Sager said.

The lifts also require a valet, adding another amenity for tenants.

“It’s becoming more common, but this is probably the biggest use of them,” Sager said.

The project team opted to place bicycle parking in an easily accessible groundfloor indoors area that includes wood paneling and six showers.

“It isn’t a dark room in the basement,” Sager said. “It’s a key element of the building. (The developers) really wanted to step up the presentation to commuters and make it nice.”

The development’s technological features include an innovative building skin to seal the buildings against inclement weather. The project team worked with Fred Shearer & Sons to pre-fabricate the metal stud framing

and sheathing of the exterior walls.

The team then utilized a custom purpose-built robot to install the panels, saving time and money, the project team wrote in its TopProjects submission.

Lease Crutcher Lewis also had to go underground with a complex system to stabilize the buildings on the site, which is in a liquefaction zone. Consultation with the city of Portland geotechnical engineers resulted in 860, 6-foot-diameter columns reaching 20 feet in depth to provide soil stabilization and flexibility during an earthquake. To withstand pressure from the water table, the columns were tied into the mat foundation with rebar uplift anchors.

Approximately 50,000 gallons a day of groundwater were filtered and treated on site as heavy rains dealt another complication to construction. Water quality exceeded drinking water standards before being discharged into the city’s storm water system, according to Lease Crutcher Lewis.

PROJECT TEAM + STATS:

Location: Portland

Cost: $61.5 million

Start Date: July 2016

Completion Date: March 2018

Owner/Developer: Project

Architect: Hacker Architects

Engineer: PAE Consulting Engineers

General Contractor: Lease Crutcher Lewis

Engineering Partners: Alliant Systems, Cherry City Electric, Humber Design Group, KPFF Consulting Engineers, Total Mechanical

Field Office Subcontractors: Alliant Systems, Aluma-Systems Concrete Construction, Apply-A-Line, Axiom Custom Products, B&B Tile and Masonry, BergerABAM, Blue Flame Specialties, Building Materials Specialties, Cedar Landscape, Cherry City Electric, Coffman Excavation, CG Gredvig Inc., Iron Horse LLC, Taylor Transport, CRJ Construction, Culver Glass, DeaMor Associates, Dero Bike Rack, DGM Systems, Electric Time, Encore Glass, Engineered Products a Pape Company, Farwest Steel Contracting, Forms & Surfaces, Fred Shearer & Sons, GC Sales Associates, General Sheet Metal Works, GeoDesign Inc., Harding Steel, Hollman Inc., Humber Design Group, Interior Technology, Jones Lang LaSalle, L.J. Pearson Construction, Landscape Forms, Lango Hansen Landscape Architects, LaRusso Concrete, Loy Clark Pipeline, Mayes Testing Engineers, McDonald & Wetle, Mid-Valley Glass & Millwork, Mobile Mini, Modern Building Systems, Morrow Equipment, Ness & Campbell Crane, Northwest Tower Crane Service, Nystrom Inc., Otis Elevator, Pacific Foundation, Park Office, Patriot Fire Protection, Pioneer Waterproofing, Plover Building Maintenance, Ralph’s Concrete Pumping, REFA Erection, RF Stearns Inc., Roedel Tile Contracting, Safway Services, Sahnow’s Air Photos, Sign Wizards, Statewide Rent-A-Fence, Sterling Floors, Total Mechanical, Town & Country Fence, Umpqua Roofing, Wessco, Western Partitions, Williamsen & Bleid

Six story project with mechanical parking rising in Hollywood

24 hour fitness, carmatrix, deacon construction, deacon development, harding steel, hollywood max station, laurel 42, lrs architects, paul boundy, ryan meyers, ryan schera, steve deacon

By Ted Perkins | July 24, 2017

Deacon Development’s Laurel 42 multifamily project in the Hollywood neighborhood will be a six-story apartment building with 100 residential units, 2,000 square feet of street-level retail and 60 parking spaces with an automated, three-stack, mechanical parking system. The building just east of the Hollywood MAX station, is targeted for completion in October of 2018. (LRS Architects)

On June 27, Deacon Development hosted a groundbreaking at 4242 N.E. Halsey Street in the Hollywood neighborhood to kick off construction of their Laurel 42 multifamily project, a six-story apartment building that will offer 100 residential units, 2,000 square feet of street-level retail and 60 parking spaces with an automated, three-stack, mechanical parking system. The building, on the long-vacant lot adjacent to 24 Hour Fitness and just east of the Hollywood MAX station, is targeted for completion in October of 2018.

“It’s been a good team effort,” said Steve Deacon, CEO of Deacon Construction and Deacon Development – both of which are headquartered in the Kerns neighborhood. “I’ve really enjoyed the process of pulling together all the thoughts and ideas from so many different folks. Our company has built thousands of apartment units, but we’ve never developed one. It’s a whole different ballgame for us. Usually we just go build what someone else has conceived.”

Deacon is part of a local ownership group that purchased the property in the spring of 2009. Originally slated for an office building, the development team began considering an apartment project for the site about two years ago. Deacon Development is developing the project, LRS Architects designed the building and Deacon Construction will be the general contractor.

“One of the goals of the project from the very beginning has been to provide a product that will fit into the neighborhood and into the community,” said Deacon. “We want to be good neighbors. We know that parking throughout the city is challenged and so we have put in about twice as much parking as what the code calls for.”

“Apartments are really the right thing for this district,” said Paul Boundy, LRS managing principal. “The Hollywood district is one of the great neighborhoods in our city and apartments are going to enhance that and help support the businesses here. This is a timeless project and we want to be a landmark for the district. The street-front will all be retail along Halsey, with big windows, a brick facade, canopies and some benches to support the pedestrian activity goals of the city and the pedestrian activity that we currently have here. The apartment lobby will have a lot of light and be a very positive space.”

The structure will have a concrete podium with five floors of wood-framed apartments.

“We tried to design and model our building to be competitive with what’s currently on the market,” said Ryan Schera, Deacon development manager. “This site was originally part of the Laurelhurst neighborhood, before I-84 went in, and was platted around 1910. Our address is on the 4200 block – and that’s how we came up with ‘Laurel 42.’ It’s an elegant name and it provides a location identifier.”

“I think it’s going to a great place to live and I hope it turns out the way we’ve envisioned,” said Deacon. “We’re right next to the transit center. We have a fitness center in our backyard. There will be a community room on the top level, facing downtown. We have a lot of bike parking and we’ll be pet friendly.”

“The club room on the sixth floor will be a really nice space,” said Boundy. “It’s going to have an outdoor patio and an indoor space, wonderful views of downtown. It will be a really nice amenity for the tenants. This building will have 51 parking spaces, which is above the code requirement. In a tight site like this, that becomes a deep challenge. So, we engaged a Carmatrix stacking system from Harding Steel.”

On June 27, Deacon Development hosted a groundbreaking in the Hollywood neighborhood to kick off construction of their Laurel 42 multifamily project. (Ted Perkins)

“This project is very special,” said Ryan Meyers, vice president of Harding Steel, the country’s oldest – and largest – automated, mechanical parking systems manufacturer and installer. “This is the furthest east of the river that we’ve been able to work. We’ve been operating in Portland for ten years. Our first project was in the Hawthorne district and we have expanded into 20 installed projects in the city, with over 15 more under contract through 2018.”

This is Harding’s third project with LRS, after two smaller projects on North Williams Avenue.

“We’ve done projects as small as five cars in Portland and as big as 134, so this is right in our sweet spot,” said Meyers. “What we’re doing here is we’ll take the space for six traditional parking stalls and, by using our Carmatrix system, we’ll turn that into 51 stalls. We’ll be using a three-stack system. The machine shuffles cars left to right and up and down, to give tenants complete access, independent of valets or additional services. It’s safe and secure. We use a simple, swipe-card identification and have automated features to close gates. Retrieval times are between a minute and a half to three minutes. The other benefit for the community is that you won’t have people circling the block, looking for street parking.”

For more information, visit www.deacon.com.

Komo News:

Inside Seattle’s first computerized car-stacking parking garage

by Lindsay Cohen | Friday, August 28th 2015

Harding Steel Carmatrix

SEATTLE – When Darcy Johnson was looking to rent a new apartment downtown, a parking spot was a deal-breaker.

“I need my car for my job and to make a living, and I don't feel that I’m a candidate for a bicycle,” said Johnson, an accountant with clients in Seattle and the suburbs. “And the public transit – as much as we‘re improving it in Seattle – I don't feel that I can depend on it.“

A building going up at 9th Avenue and Pine Street caught Johnson‘s eye – not only for its environmentally-friendly rooftop but for the ground-level parking plan: a brand-new, high-tech car-stacking system that would be the first of its kind in the Emerald City.

”It‘s not just a gizmo. It‘s not just a gadget. It‘s not something to get media attention. It‘s a way to have a car downtown,” Johnson said. “Look at all the cars we have downtown in that small space. It just makes perfect sense.“

A standard parking arrangement would have left space for just 10 cars, said Sara Englehart, the business manager at the Nine and Pine Apartments. In lieu of that, the developer installed a computerized Carmatrix system, which allows the building to park three times the number of cars in the same amount of space, with tenants operating it on their own.

”Our building is built on top of the bus tunnel. Normally, in a city setting, you would dig down and do underground garages. We can’t do that here,“ Englehart said. ”So we have to take the space that we have and maximize the square footage we can use.”

Residents use a swipe card to activate a keypad and then punch in a code to access their car. Vehicles then shift side-to-side and up-and-down until the requested car is at ground level.

There are other car-stacking systems in Seattle, Englehart added, but none that operate without the assistance of a valet.

”We are the first so far. I know we've had a lot of people check us out,“ said Englehart, adding that the city required the building to allow the public to view the system from the ground-floor sidewalk outside. “I’m sure we’ll see more to come.“

Johnson hopes the system moves not only cars – but minds, when it comes to maximizing space.

”The bottom line in this situation is we need affordable and available parking in the city of Seattle,“ Johnson said. “I would climb on a ladder for 10 stories to get up to my car if I had to because I need that car. That’s made the difference for me.“

A Mass Timber Tower Rises in Portland

By Will Macht

PUBLISHED November 19, 2018, urbanland.uli.org

Upon completion at eight stories, Carbon 12 was the tallest CLT mass timber building in the United States. (Andrew Pogue)

Until recently, buildings taller than five stories had to be constructed of steel or reinforced concrete, both of which require about 80 percent more energy to produce and represent about 200 percent more greenhouse gas emissions than cross-laminated timber (CLT), a new engineered wood product.

Portland developer Ben Kaiser of the Kaiser Group recently completed the tallest American CLT mass timber building—an eight-story, 16-unit condominium/retail tower on an 8,470-square-foot (787 sq m) lot …

To sell high-end condominiums at premium prices to buyers who almost certainly would own cars, Kaiser needed to provide enough parking. On a site as small as the tower’s, building underground parking would have required underground ramps steeper than the code allowed or which spiraled so much as to have yielded too few spaces. Besides, the CLT tower’s small-grid, deep piling would have interfered with parking. So, Kaiser experimented with an automated underground parking system made by Wohr GmbH, a company based in Friolzheim, Germany. While mechanical parking lifts have been installed in Portland, this is the first fully robotic parking system in Oregon.

The robotic parking system stores 22 cars on two underground levels. Unlike parking structures, no special ventilation, lighting, or security is required; no elevators, stairs, or fire exits are needed to move patrons; cars are safe from damage, theft, and vandalism; and no vehicle emissions can seep into the building above. (Harding Steel)

CARMATRIX: Limited parking? No problem

With little room for much-needed car slots, Minneapolis developers turned to a Rubik's Cube stacking system for their project.

By Jim Buchta | Star Tribune | SEPTEMBER 28, 2018 — 10:17PM

The garage at the M on Hennepin features the car matrix parking system that can shuffle cars on its two levels, allowing residents to have 24 / 7 access. (DAVID JOLES • STAR TRIBUNE)

As redevelopment sites go, 116 E. Hennepin Av. in Minneapolis was a prize. The nearly half-block parcel housed four old storefront buildings, including the popular Nye’s Polonaise Room, in a bustling neighborhood just a block from the leafy banks of the Mississippi River.

From a construction standpoint, the sloped, irregular-shaped site was a major league headache.

Two of the four buildings had historic protection and couldn’t be significantly altered; the oldest church in the city was right next door, and the buildings sat atop a deep deposit of bedrock that made blasting a hole deep enough to build a standard underground parking garage financially and logistically impractical.

Those site challenges and the complexity of stitching together the old and new buildings quickly made this the most complicated that Katie Anthony, a project manager for Schafer Richardson, had ever tackled.

“The methods for getting rid of that bedrock were not palatable,” said Anthony. “There were multiple challenges.”

Schafer Richardson, a seasoned Minneapolis-based developer, originally wanted to build a nearly 30-story concrete tower atop several levels of above-ground parking.

For a variety of reasons, that plan was scuttled in favor of a stick-built, low-rise apartment building that would replace two of the buildings and wrap around and sit atop the remaining two buildings.

Apartment developers got creative after working with parking challenges at the cramped Nye’s Polonaise Room site. (DAVID JOLES • STAR TRIBUNE)

Dramatically shrinking the height of the building solved several problems, but created one that was nearly insurmountable: A multilevel, above-ground parking garage was no longer feasible. Neither was forgoing a heated parking garage with enough spaces for every unit.

With population density on the rise in that part of the city, parking is highly coveted. In some condo buildings in the area, spaces fetch upward of $50,000, so not including sufficient parking would put the 67-unit building at a major competitive disadvantage.

So Schafer Richardson hired Denver-based Harding Steel to build what’s being called the first residential semi-automated, mechanical car stacking system in the Midwest.

The company’s CARMATRIX is essentially a Rubik’s Cube for cars.

The system is a grid of steel frames that supports a series of stacked galvanized steel platforms that move up and down and side to side. A metal gate closes behind the cars after they enter or leave the platform.

For each grouping of platforms, a vacant space at grade level enables the upper and lower platforms to move around to access a vehicle when it’s called by its owner using a portable remote control.

Unlike garage elevators that simply lift vehicles from one level to the next, and typical car storage systems that are operated by professional car parkers, the CARMATRIX enables residents to have an assigned space and park their own cars, eliminating the need for an attendant or a valet parker, Anthony said. The entire process takes just a couple minutes.

Because the M on Hennepin site was heavily sloped, the company was able to build a second traditional at-grade parking garage, giving residents another option. There are 26 spaces in the CARMATRIX and 37 in the traditional garage.

Though there was a steep learning curve for the building manager and the first residents, the CARMATRIX hasn’t been an obstacle to renting units. Since the building opened late least year, it’s been fully occupied.

In addition to the complexities of the site, designing the building around the CARMATRIX wasn’t easy. Anthony credited ESG Architects and Frana Cos. with figuring out how to tie the metal structure to the post-tension concrete structure.

A team from Twin Cities-based Rebel Electric flew to Seattle to inspect another system before installing the one at the M on Hennepin; they’ve become a local expert on the system, Anthony said.

Such systems are well-suited for cities where land prices are soaring and developable space is at a premium.

Ryan Myers, Harding Steel vice president, said that demand for its CARMATRIX and Combilift products, which are both based on the “puzzle” concept, has been on the rise.

The company is working with a developer in Hudson, Wis., but that project is still in the planning stages.

He said the system costs $14,000 to $16,000 per car, depending on options and the number of stalls.

Myers said developers in many second-tier and even some small but fast-growing cities, including Portland, Maine and Portland, Ore., are considering the option.

“It’s a way to optimize parking and development design and not be forced into hiring a valet operator to manage parking,” said Myers.

Apartment developers got creative after working with parking challenges at the cramped Nye’s Polonaise Room site.

August 29, 2018

The History of Mechanical Parking in the United States

The mechanical and automated parking systems industry in the United States has been flourishing for fifty years. While many newcomers to the industry believe that this is new, it has been a small but steadily growing industry for decades. The application of various lift technologies to commercial parking in urban centers has been regularly utilized to both increase parking capacity as well as increase parking revenue. Harding Steel has been at the forefront of this technology since 1968.

Traditionally mechanical parking has utilized hydraulic lift systems that “stack” cars on top of one another. At the very basic concept this is often referred to as a “double stacker” – which we refer to as the SUV Lift. The hydraulic lift systems range from double, triple, and up to four levels of parking on a single traditional parking space dimension. Historically the market for these lift systems have been outdoor stand-alone parking lots in New York City, Boston, Philadelphia, and Washington DC. The demand of these systems has spread across the country, with Harding Steel being the leader in a majority of the metro markets.

The early adopters of mechanical parking technologies have been commercial parking facilities not tied to mixed use or multifamily properties. These facilities are valet attended and usually operated on a lease basis from the property owner allowing the owner to double, triple, or quadruple revenue on a single stall. As these lots have been sold or repurposed for real estate development, the industry has seen a shift of both application for traditional parking systems as well as a demand for newer technology.

The demand for mechanical parking systems has found the way inside of commercial real estate development with either a mixed use or residential component. Valet operation is still very common across the country as both an luxury amenity and a design intent for the larger developments. Larger scale properties with a mixed-use program can often support the cost of valet operations, allowing them to utilize less expensive lifts over other alternatives.

The true mechanical and automated parking industry shift started to occur in the early 2000’s with the increase of smaller urban infill real estate projects. This shift created a demand for what is known as self-park or “independent parking.” It was at this time Harding Steel rolled out the first semi-automated parking systems in the United States called CARMATRIX. CARMATRIX allowed residents to be assigned a stall and through computer controls shuffle cars around inside of the “puzzle” to access them at grade. This removed the need for a valet in these smaller projects, unlocked development potential, and saved developers both money and time on bring projects out of the ground.

As the earliest adopters in the US for this technology, Harding Steel has seen the self-park industry grow to pit-based parking (subterranean parking) all the way through fully automated parking. Harding Steel provides solutions through every parking system category from simple parking stackers all the way through fully automated parking solutions. We install and service our equipment coast to coast.

Please contact Harding Steel to review any project or development you are working on. We are happy to work with you to create the solution that fits best into your development.